Organotin mercaptides are unbeatable in terms of stability, color, transparency of the final product, and processing window. However, we should also be aware that they have some disadvantages compared to tin-free alternatives regarding weathering.

Let’s explore more about Antimony stabilisers:

As noticed recently, we have witnessed a resurgence of antimony mercaptides. They are closely related to organotin mercaptides both chemically and in terms of processing, and they are also more cost-effective.

Now the question arises regarding weathering: Are they more similar to organotin mercaptides or PVC lead stabilizers?

There is actually no literature on this. If they were similar to tin stabilizers, they may require more titanium dioxide. If they were similar to lead based PVC stabilizers, discoloration under light exposure would be expected. From lead stabilizers, we know that photogreying is further intensified with glycerol partial esters. So, we have examined this in various dry blends in the Xenotest.

Dryblends:

All dryblend contain: 100 phr PVC (k=67), 3 phr CaCarbonate, uncoated, 2 phr processing aid, 0.5 phr Titanium dioxide, 1 phr GMS (glycerol monostearate, 90%ic) or PE wax and 1 or 2 phr stabiliser.

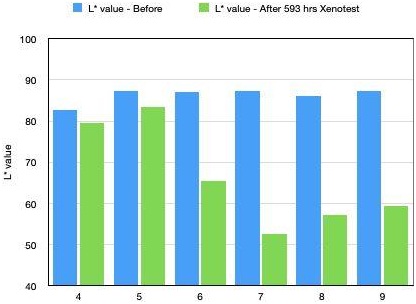

Trial 4: 0.5 phr TiO2, PE wax, 1 phr methyltin mercaptide with 19% Sn (MTM) Trial 5: 0.5 phr TiO2, PE wax, 2 phr MTM

Trial 6: 0.5 phr TiO2, PE wax, 1 phr Antimony mercaptide (AM)

Trial 7: 0.5 phr TiO2, PE wax, 2 phr AM

Trial 8: 0.5 phr TiO2, GMS, 1 phr AM

Trial 9: 0.5 phr TiO2, GMS, 2 phr AM

After 593 hours in the Xenotest, we measured the Lab* values and observed the following: With 0.5 phr TiO2, the L-value decreases as follows:

MTM only by 3-4 units

AM with PE wax by 20 to 35 units (the higher the dosage of AM, the stronger the reduction)

AM with GMS by approximately 30 units, regardless of the dosage of AM.

There are clear indications that metallic antimony is formed, leading to greying similar to the photogreying seen with lead stabilizers.

Conclusion: Antimony mercaptides are either not suitable or only conditionally suitable for outdoor applications, as they are highly likely to cause greying in the presence of small amounts of titanium dioxide. Further investigations are planned and necessary to either support or potentially refute the current hypothesis.

Keywords:

#pvc #stabiliser #organotin #organotinstabiliser #antimonystabiliser #antimonymercaptide #weathering #photogreying

The PVC stabilizer market in India is experiencing significant growth and transformation. As the PVC Industry expands and environmental concerns become more prominent, the demand for advanced, sustainable stabilisers is expected to rise. Platinum Industries Ltd., PVC stabilizer manufacturers in India, has always pre-empted this boom, investing in technological innovation that can drive the PVC and CPVC stabiliser market towards a high quality, more sustainable and efficient future. Being a member of the Indian Vinyl Council, Platinum Industries Ltd. is among the leading manufacturers of organic based stabilizers that exceed industry standards.

Platinum Industries Ltd., a member of Indian Vinyl Council (IVC)