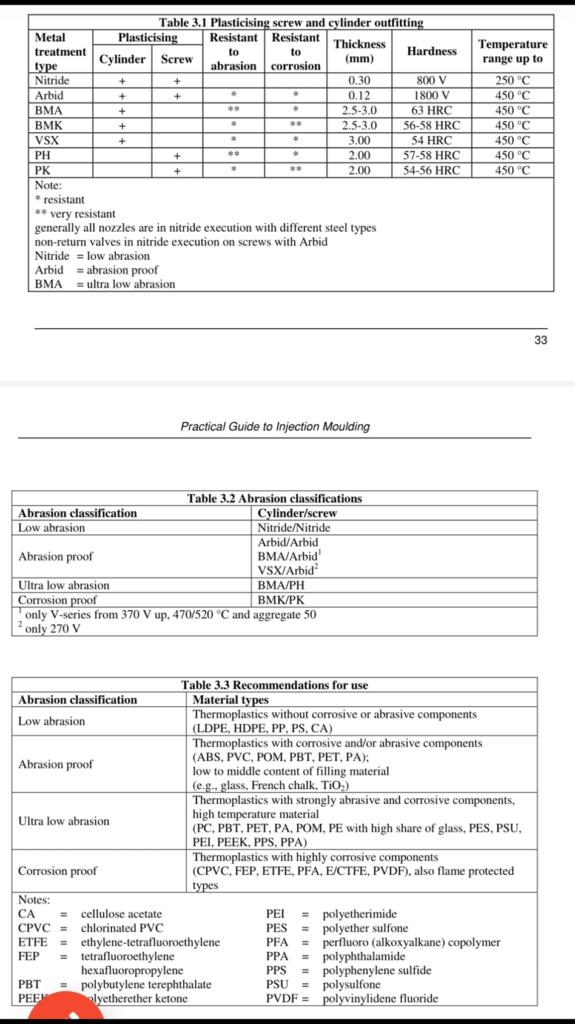

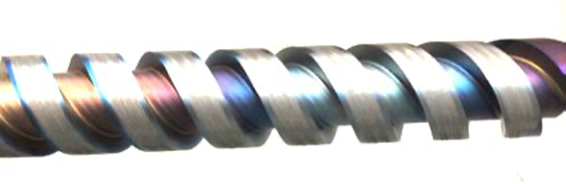

I have been working in the PVC industry for more than 30 years. I have seen many problems and resolved most of them. However, the issue depicted in the image has only occurred twice in all these years. During a routine inspection, a processor noticed this discoloration on their extruder screws; Figure

- Figure 1 Discoloured extruder screw

This seems to be rather unusual. I typically associate such discolorations only with my youth and the chromed exhaust manifold of my motorcycle. It is called tarnish colours; Table 1. However, different materials have different colors at the same temperature. It depends a lot from their chemical composition….

Table 1 Tarnish colours of unalloyed steel (source: Wikipedia, the Free Encyclopedia (German version)

| Temperature/°C | ||

| White yellow | | |

| Golden yellow | 220 | |

| Straw yellow | 230 | |

| Yellow brown | 240 | |

| Braunrot | 250 | |

| Red | 260 | |

| Purple | 270 | |

| Violet | 280 | |

| Dark blue | 290 | |

| Cornflower blue | 300 | |

| Light blue | 320 | |

| Blue-grey | 340 | |

| Grey | 360 | |

In the past, I examined a screw at the FELMI-ZFE Institut für Elektronenmikroskopie und Nanoanalytik – Zentrum für Elektronenmikroskopie and couldn’t find any connection to the stabilizer.

The discoloration can be attributed to various reasons. Here are some possible causes:

– Oxidation: Extruder screws may turn blue due to oxidation, which occurs when the metals in the screw react with oxygen in the air. This often happens when the screw is exposed to high temperatures over extended periods.

– Contaminants in the plastic material: Discoloration of the screw can result from contaminants in the plastic material itself. These contaminants may include metals or other chemical substances that come into contact with the screw during the extrusion process.

– Use of additives: Certain additives or dyes/pigments mixed into the plastic can lead to discoloration of the extruder screw. Some dyes or additives may have a tendency to color the screw under specific conditions.

– Material wear: Intensive use can lead to wear and tear on the extruder screw. Abrasive particles could accumulate on the screw surface, contributing to discoloration.

– Wrong screw design: an extremely high pressure was being created, near the start of the screw, due to a very high amount of material being delivered by the grooved feed section. This resulted and very large forces (pressure and shear stress) acting on the screw surface, and particularly, in the primary/solids channel. These forces were so high that they discolored the screw and, ultimately, eroded the surface.

– Screw cooling: internal cooling of screws is not effective or too much shearing in compression zones.

– Regarding corrosion: Extruder was not purged before shutting down.

– Wrong steel quality

To address or prevent the issue of blue discoloration, consider the following measures:

– Reviewing extrusion parameters and conditions to ensure that temperatures are not excessively high.

– Using high-quality plastic materials free from impurities.

– Checking the composition of additives and dyes used.

– Regular maintenance of the extruder screw to minimize wear.

It’s important to note that determining the exact cause of the discoloration may require a thorough analysis of production conditions and material composition. If issues persist, it would be advisable to consult with a professional or engineer specializing in plastic processing.

There’s a practical guide which shows which type of treatment is required for screw compared to plastic material used. (source: https://www.linkedin.com/in/dr-michael-schiller-32690813/recent-activity/all/#; Comment by Mohammed Abdelaziz; accessed on 08.30.2024.)

The PVC stabiliser market in India is experiencing significant growth and transformation. As the PVC industry expands and environmental concerns become more prominent, the demand for advanced, sustainable stabilisers is expected to rise. Platinum Industries has always preempted this boom, investing in technological innovations that can drive the PVC and CPVC stabiliser market towards a more sustainable and efficient future.

Platinum Industries Ltd. the leading PVC and CPVC stabiliser manufacturer in India, is a member of the Indian Vinyl Council (IVC).

Platinum Industries Ltd., a member of Indian Vinyl Council (IVC)